Views: 0 Author: Site Editor Publish Time: 2025-03-11 Origin: Site

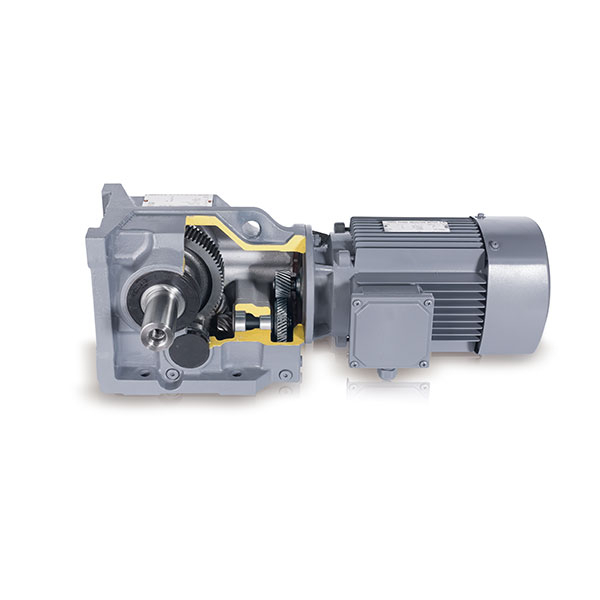

In the rapidly evolving world of industrial machinery, efficiency and reliability are paramount. The K Series Helical Gearbox, offered by RICHMAN UNIVERSAL SOURCING CO LIMITED (RICHMAN), stands out as a revolutionary product designed to enhance operational efficiency across various industries. This article delves into the features, benefits, and applications of the K Series Helical Gearbox, highlighting how it can transform industrial operations.

Helical gearboxes are renowned for their ability to transmit power efficiently and quietly. Unlike spur gears, helical gears feature angled teeth, which allows for smoother and more gradual engagement. This design minimizes noise and vibration, making helical gearboxes ideal for high-speed applications. The K Series, in particular, is engineered to optimize these advantages, providing superior performance in demanding environments.

The K Series Helical Gearbox by RICHMAN is distinguished by several key features that contribute to its enhanced efficiency:

Precision Engineering: The K Series is manufactured with high precision to ensure optimal alignment and minimal backlash, resulting in more efficient power transmission.

Robust Construction: Built with high-quality materials, the K Series can withstand heavy loads and harsh operating conditions, ensuring long-term durability.

Compact Design: Despite its robust capabilities, the K Series is designed to be compact, saving valuable space in industrial setups.

High Torque Capacity: The gearbox is capable of handling high torque levels, making it suitable for a wide range of applications.

Energy Efficiency: With reduced friction and heat generation, the K Series contributes to lower energy consumption and operational costs.

Implementing the K Series Helical Gearbox in industrial operations offers numerous benefits:

Improved Operational Efficiency: The precision engineering and high torque capacity of the K Series lead to more efficient power transmission, reducing energy losses and improving overall operational efficiency.

Reduced Maintenance Costs: The robust construction and high-quality materials used in the K Series minimize wear and tear, reducing the frequency and cost of maintenance.

Enhanced Reliability: With its ability to operate smoothly under high-speed conditions, the K Series ensures reliable performance, minimizing downtime and production disruptions.

Versatility: The K Series is suitable for a wide range of applications, from conveyor systems and mixers to cranes and extruders, making it a versatile choice for various industries.

The versatility of the K Series Helical Gearbox makes it applicable in numerous industries:

Manufacturing: In manufacturing plants, the K Series is used in conveyor systems, mixers, and other machinery requiring efficient power transmission.

Mining: The robust construction and high torque capacity make the K Series ideal for mining equipment, where reliability and durability are crucial.

Automotive: In the automotive industry, the K Series aids in the efficient operation of assembly lines and testing equipment.

Food and Beverage: The smooth operation and low noise levels of the K Series make it suitable for food processing and packaging machinery.

In the industrial sector, the efficiency of machinery is a critical factor influencing productivity and profitability. Gearboxes play a vital role in this equation, as they are responsible for transmitting power from motors to various machine components. An efficient gearbox not only enhances the performance of machinery but also contributes to energy savings and reduced operational costs.

With the global push towards sustainability, industries are increasingly focusing on energy-efficient solutions. Gearboxes like the K Series align with this trend by offering high efficiency and reliability, helping companies achieve their sustainability goals while maintaining competitive advantages.

The development of gearboxes has seen significant advancements over the years, driven by the need for higher efficiency and performance. Modern gearboxes, including the K Series, incorporate advanced materials, precision engineering, and innovative design features to meet the demands of contemporary industrial applications.

For instance, the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies has enabled manufacturers like RICHMAN to produce gearboxes with exceptional precision and consistency. Additionally, the integration of smart technologies in gearbox design allows for real-time monitoring and predictive maintenance, further enhancing efficiency and reliability.

As industries continue to evolve, the demand for efficient and reliable gearboxes will only increase. The K Series Helical Gearbox by RICHMAN represents a significant step forward in gearbox technology, offering unparalleled efficiency, durability, and versatility. By investing in advanced gearboxes like the K Series, companies can enhance their operational efficiency, reduce costs, and achieve their sustainability objectives.

In conclusion, the K Series Helical Gearbox is not just a component of machinery; it is a critical factor in the success of industrial operations. As industries strive for greater efficiency and sustainability, gearboxes like the K Series will play an essential role in shaping the future of industrial machinery.