Views: 0 Author: Site Editor Publish Time: 2025-05-28 Origin: Site

In the ever-evolving landscape of industrial machinery and automation, gear reducer systems play a pivotal role. These systems are essential for optimizing the performance of various machines by reducing speed and increasing torque. At RICHMAN UNIVERSAL SOURCING CO LIMITED, commonly referred to as RICHMAN, we are dedicated to exploring the potential of gear reducer systems and providing innovative solutions to enhance industrial efficiency.

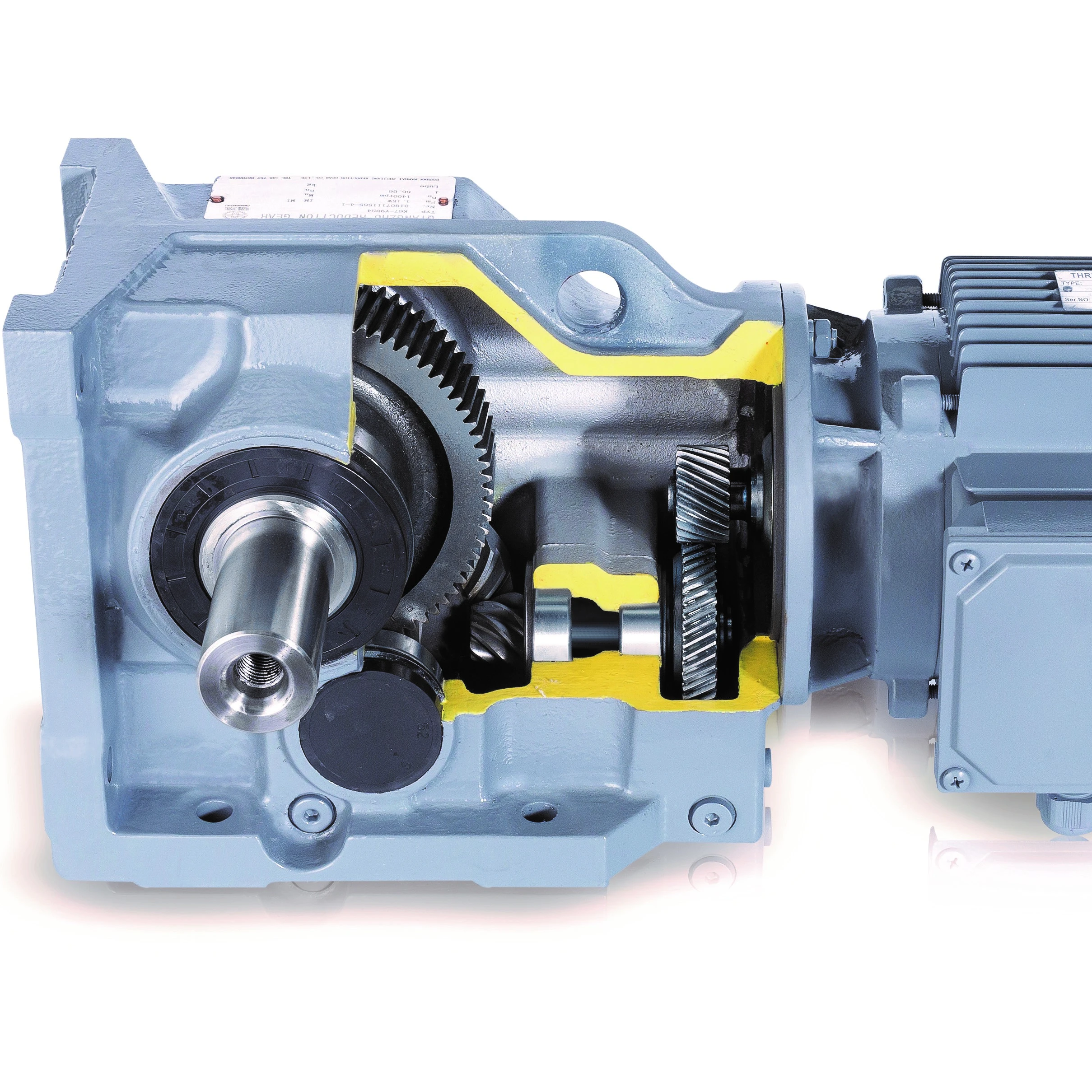

Gear reducer systems, also known as gearboxes or speed reducers, are mechanical devices used to decrease the speed of an input power source while increasing the torque. This adjustment is crucial for ensuring that machinery operates at optimal speeds, enhancing performance and prolonging the lifespan of the equipment.

parallel shaft helical geared motor

efficiency helical geared motor

helical bevel geared motor

round aluminum worm gear reductor

VF series worm gear reducer

Chinese made worm elevator

The primary components of gear reducer systems include gears, shafts, and bearings. These components work in harmony to achieve the desired speed reduction and torque increase. The design and configuration of these components vary based on the application and specific requirements of the machinery.

There are several types of gear reducers, each with unique characteristics and applications. At RICHMAN, we provide a wide range of gear reducer systems tailored to meet diverse industrial needs. The most common types include:

Helical Gear Reducers: Known for their efficiency and smooth operation, helical gear reducers are ideal for high-speed applications.

Worm Gear Reducers: These reducers are suitable for applications requiring high torque and low speed, offering excellent shock absorption capabilities.

Planetary Gear Reducers: With a compact design and high torque density, planetary gear reducers are perfect for precision applications.

Bevel Gear Reducers: Used for applications requiring a change in the direction of the drive, bevel gear reducers are versatile and efficient.

Gear reducer systems are integral to various industries, including manufacturing, automotive, aerospace, and renewable energy. Their ability to enhance machine performance while reducing energy consumption makes them indispensable in modern industrial processes.

In the manufacturing sector, gear reducers are used in conveyor systems, mixers, and packaging machinery. They ensure that these machines operate efficiently, reducing downtime and maintenance costs. In the automotive industry, gear reducers are crucial for electric vehicles, where they help in optimizing motor performance and increasing vehicle range.

The aerospace industry relies on gear reducers for applications such as aircraft landing gear and flight control systems. These systems demand precision and reliability, which gear reducers provide. In the renewable energy sector, gear reducers are used in wind turbines to convert the slow rotation of the blades into the high-speed rotation required by generators.

At RICHMAN, we are committed to staying at the forefront of gear reducer technology. Recent advancements have focused on improving efficiency, reducing noise, and enhancing durability. These improvements are achieved through the use of advanced materials, precision manufacturing techniques, and innovative design approaches.

One significant advancement is the development of high-efficiency gear reducers, which minimize energy loss and reduce operational costs. Additionally, the integration of smart technology allows for real-time monitoring and predictive maintenance, ensuring optimal performance and reducing the risk of unexpected failures.

As a leader in the industry, RICHMAN UNIVERSAL SOURCING CO LIMITED is dedicated to providing cutting-edge gear reducer solutions. Our commitment to quality and innovation has positioned us as a trusted partner for industries worldwide.

Our product portfolio includes a wide range of gear reducers designed to meet the specific needs of our clients. We offer customized solutions, ensuring that each gear reducer is tailored to the unique requirements of the application. Our team of experts works closely with clients to understand their needs and deliver solutions that exceed expectations.

At RICHMAN, quality assurance is a top priority. We adhere to stringent quality control measures throughout the manufacturing process, ensuring that our gear reducers meet the highest standards of performance and reliability. Our commitment to quality extends beyond the production line, with comprehensive after-sales support and maintenance services.

Our customer support team is available to assist clients with any inquiries or issues they may encounter. We believe in building long-term relationships with our clients, providing ongoing support and guidance to ensure their success.

In today's world, environmental sustainability is a crucial consideration for industries. Gear reducer systems play a significant role in reducing energy consumption and minimizing the environmental impact of industrial processes. By optimizing machine performance, gear reducers contribute to lower energy usage and reduced carbon emissions.

At RICHMAN, we are committed to promoting sustainable practices in the industry. Our gear reducers are designed with energy efficiency in mind, helping our clients achieve their sustainability goals. We also prioritize the use of eco-friendly materials and manufacturing processes, minimizing our environmental footprint.

The future of gear reducer systems is promising, with ongoing advancements in technology and design. As industries continue to evolve, the demand for efficient and reliable gear reducers will increase. At RICHMAN, we are excited about the potential of emerging technologies such as artificial intelligence and the Internet of Things (IoT) to revolutionize gear reducer systems.

These technologies offer the potential for enhanced monitoring and control, allowing for real-time adjustments and predictive maintenance. By harnessing the power of data, gear reducers can achieve unprecedented levels of efficiency and reliability, transforming the way industries operate.

Gear reducer systems are a vital component of modern industrial machinery, offering significant benefits in terms of performance, efficiency, and sustainability. At RICHMAN UNIVERSAL SOURCING CO LIMITED, we are committed to unlocking the full potential of gear reducer systems, providing innovative solutions that drive industry forward.

With a focus on quality, customer support, and environmental sustainability, RICHMAN is a trusted partner for industries worldwide. As we look to the future, we are excited about the possibilities that lie ahead and remain dedicated to delivering the best gear reducer solutions to our clients.

For more information about our products and services, please visit our website or contact our team of experts. Together, we can unlock the potential of gear reducer systems and drive industrial innovation.