Views: 0 Author: Site Editor Publish Time: 2025-03-19 Origin: Site

In the ever-evolving world of mechanical engineering, the demand for efficiency, durability, and sustainability has never been higher. Industries spanning automotive, agriculture, manufacturing, and energy are constantly looking for innovative solutions that not only enhance performance but also reduce environmental impact. One such solution lies in the advancements of helical gearbox technology. At the forefront of this innovation is RICHMAN UNIVERSAL SOURCING CO LIMITED (RICHMAN), a company dedicated to pioneering sustainable engineering solutions through cutting-edge gearbox designs.

Helical gearboxes, known for their precision and reliability, are increasingly being adopted across industries due to their ability to handle higher loads, reduce noise, and improve energy efficiency. With sustainability becoming a global priority, the integration of innovative helical gearbox designs is proving to be a game-changer in achieving greener engineering practices. This article delves into how RICHMAN is leading the charge in helical gearbox innovations and highlights the broader implications for sustainable engineering.

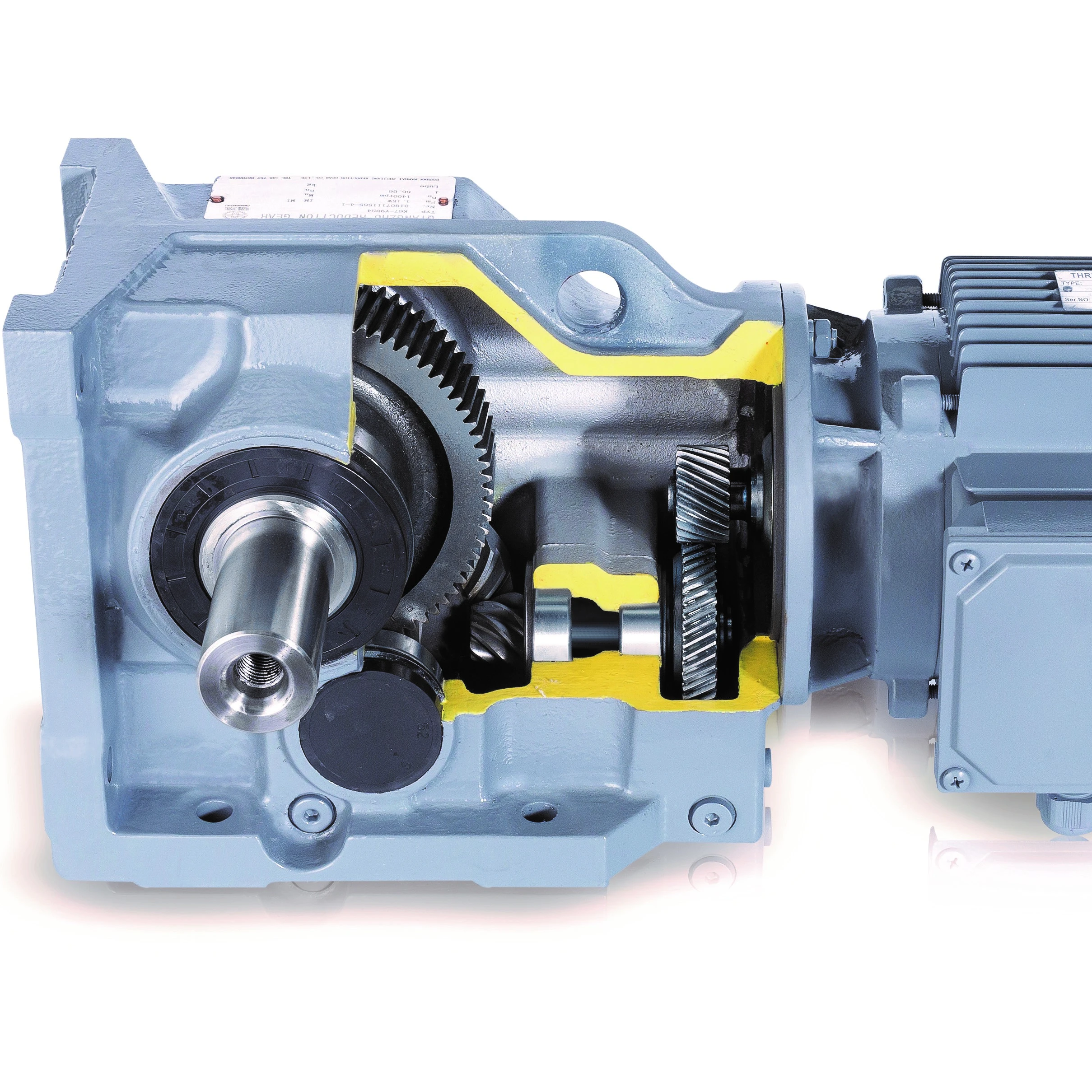

A helical gearbox is a type of mechanical transmission device that uses angled teeth on cylindrical gears to transmit power and torque between shafts. Unlike spur gears, which have straight teeth, the angled design of helical gears allows for smoother and quieter operation. This unique configuration offers several advantages:

Enhanced Load Capacity: The angled teeth provide a larger contact area, enabling the gearbox to handle higher torque and load capacities.

Reduced Noise and Vibration: The gradual engagement of teeth minimizes noise and vibration, making helical gearboxes ideal for applications requiring quiet operation.

Improved Durability: The even distribution of load across the teeth reduces wear and tear, extending the lifespan of the gearbox.

Energy Efficiency: The smooth transmission of power minimizes energy losses, contributing to overall system efficiency.

These advantages make helical gearboxes a preferred choice for industries aiming to optimize performance while adhering to sustainable practices. RICHMAN has taken these benefits a step further by integrating advanced materials, innovative designs, and eco-friendly manufacturing processes into their helical gearbox solutions.

As a global leader in mechanical transmission solutions, RICHMAN has long recognized the importance of sustainability in engineering. The company’s commitment to reducing environmental impact is evident in its approach to helical gearbox innovation. By leveraging state-of-the-art technology and adhering to strict environmental standards, RICHMAN is setting new benchmarks in sustainable engineering.

One of the key aspects of RICHMAN's helical gearbox innovation is the use of eco-friendly materials. The company employs advanced alloys and composites that are not only lightweight but also recyclable. These materials reduce the carbon footprint of the manufacturing process and ensure that the gearboxes can be recycled at the end of their lifecycle.

RICHMAN's helical gearboxes are designed with energy efficiency in mind. The optimized gear tooth profiles and precision engineering minimize frictional losses, ensuring maximum power transmission with minimal energy consumption. This is particularly important in industries such as renewable energy, where efficiency directly impacts the sustainability of the system.

RICHMAN employs advanced manufacturing techniques such as 3D printing and computer-aided design (CAD) to reduce material waste and energy usage during production. These techniques also allow for greater customization, enabling the company to tailor its gearboxes to specific applications while maintaining high efficiency and durability.

In line with its commitment to sustainability, RICHMAN conducts comprehensive lifecycle assessments for its helical gearboxes. This involves analyzing the environmental impact of the product from raw material extraction to disposal. By identifying areas for improvement, the company ensures that its products are as eco-friendly as possible. Additionally, RICHMAN has implemented recycling programs to recover and reuse materials from old gearboxes, further reducing waste.

The versatility and efficiency of RICHMAN's helical gearboxes make them suitable for a wide range of applications, particularly in industries focused on sustainability. Here are some examples:

Helical gearboxes play a crucial role in wind turbines, where they are used to transfer power from the rotor to the generator. RICHMAN's energy-efficient designs ensure optimal performance, helping to maximize the output of renewable energy systems while minimizing maintenance requirements.

The automotive industry is undergoing a significant shift towards electric vehicles, and helical gearboxes are a key component in EV drivetrains. RICHMAN's lightweight and durable gearboxes contribute to improved vehicle efficiency and reduced energy consumption, aligning with the sustainability goals of the EV sector.

In manufacturing and automation, helical gearboxes are used in conveyor systems, robotics, and other machinery. RICHMAN's innovations in noise reduction and durability enhance the performance of these systems while reducing energy usage and operational costs.

Agricultural machinery such as tractors and harvesters rely on helical gearboxes for power transmission. RICHMAN's robust and efficient designs ensure reliable operation in demanding environments, helping farmers adopt more sustainable practices.

While helical gearbox technology has made significant strides, there are still challenges to overcome. For instance, the development of even more efficient materials and the integration of smart technologies such as IoT and AI into gearbox systems are areas that require further research and innovation. RICHMAN is actively investing in these areas, aiming to stay ahead of the curve and continue driving sustainable engineering forward.

Looking ahead, the demand for helical gearboxes is expected to grow as industries increasingly prioritize sustainability. RICHMAN's focus on innovation, combined with its commitment to environmental stewardship, positions the company as a key player in shaping the future of sustainable engineering.

As the world grapples with the challenges of climate change and resource depletion, the need for sustainable engineering solutions has never been more urgent. Helical gearbox innovations, spearheaded by companies like RICHMAN UNIVERSAL SOURCING CO LIMITED, are playing a vital role in addressing these challenges. By combining advanced technology with eco-friendly practices, RICHMAN is not only enhancing the performance and reliability of its products but also contributing to a greener, more sustainable future.

From renewable energy and electric vehicles to industrial automation and agriculture, the applications of RICHMAN's helical gearboxes are vast and impactful. As industries continue to evolve, the company's dedication to innovation and sustainability will undoubtedly drive further advancements in helical gearbox technology, paving the way for a brighter and more sustainable tomorrow.

Tags:Gear Reducer supplier,Gear Reducer application,K Series Helical Gearbox,R Series Helical Gearbox