Views: 0 Author: Site Editor Publish Time: 2025-05-07 Origin: Site

In the world of industrial machinery, durability and efficiency are paramount. Businesses across industries such as manufacturing, construction, and energy heavily rely on robust mechanical systems to ensure uninterrupted operations. One of the critical components in these systems is the gearbox, which plays a vital role in power transmission. Among the various types of gearboxes, the helical gearbox stands out for its superior performance and durability. RICHMAN UNIVERSAL SOURCING CO LIMITED, also known as RICHMAN, has emerged as a trusted name in the manufacture of high-quality helical gearboxes designed to meet the rigorous demands of industrial applications.

This article delves into how RICHMAN ensures the durability of its helical gearboxes, the advanced manufacturing processes it employs, and the reasons why industries across the globe prefer RICHMAN's products. Additionally, we will explore the importance of helical gearboxes in industrial applications and discuss the trends shaping the future of gearbox technology.

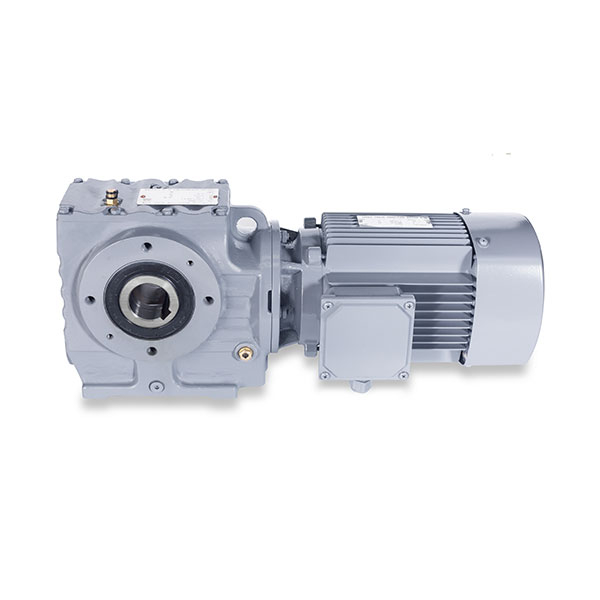

A helical gearbox is a type of gear system that uses helical gears to transmit power. Unlike spur gears, which have straight teeth, helical gears feature teeth that are cut at an angle to the gear axis. This design allows for smoother and quieter operation, making helical gearboxes ideal for high-speed and high-load applications. They are widely used in industries such as automotive, mining, food processing, and material handling.

Helical gearboxes offer several advantages, including high efficiency, durability, and the ability to handle heavy loads. However, achieving these benefits requires precision engineering and high-quality materials. This is where RICHMAN excels, leveraging its expertise and state-of-the-art technology to produce gearboxes that meet the highest standards of performance and reliability.

The foundation of any durable gearbox lies in the materials used. RICHMAN prioritizes the use of high-grade materials such as alloy steels and carbon steels, which are known for their strength and resistance to wear and tear. The company also employs advanced heat treatment processes to enhance the hardness and durability of the gears, ensuring they can withstand the rigors of industrial applications.

Precision is key to the performance and longevity of a helical gearbox. RICHMAN utilizes cutting-edge CNC machining technology to achieve high levels of accuracy in gear manufacturing. This ensures that the gear teeth mesh perfectly, reducing friction and wear over time. The company's engineering team also conducts extensive simulations and testing to optimize the design of each gearbox for maximum durability.

RICHMAN employs a range of advanced manufacturing processes to produce its helical gearboxes. These include:

Gear Hobbing: A specialized machining process used to cut the helical teeth with high precision.

Heat Treatment: Techniques such as carburizing and quenching are used to enhance the hardness and wear resistance of the gears.

Surface Finishing: Processes like grinding and polishing are used to improve the surface quality of the gears, reducing friction and enhancing durability.

Quality control is an integral part of RICHMAN's manufacturing process. The company adheres to strict quality standards, conducting multiple inspections and tests at various stages of production. From raw material inspection to final assembly testing, every step is meticulously monitored to ensure the highest level of quality and reliability.

Understanding that different industries have unique requirements, RICHMAN offers customized gearbox solutions tailored to specific applications. Whether it's a gearbox for a high-torque mining application or a compact unit for a food processing line, RICHMAN designs its products to meet the exact needs of its clients, ensuring optimal performance and durability.

Helical gearboxes are indispensable in modern industrial machinery due to their ability to handle high loads and operate efficiently. Their design allows for continuous power transmission, making them ideal for applications that require high-speed operation. Here are some key reasons why helical gearboxes are preferred in industrial settings:

High Efficiency: Helical gearboxes have a high efficiency rate, often exceeding 90%, which translates to energy savings and reduced operational costs.

Durability: The angled teeth of helical gears distribute load more evenly, reducing stress on individual teeth and enhancing the overall lifespan of the gearbox.

Noise Reduction: The gradual engagement of helical gear teeth results in smoother operation and less noise compared to spur gears.

Versatility: Helical gearboxes can be used in a wide range of applications, from conveyor systems to wind turbines.

The industrial gearbox market is constantly evolving, driven by advancements in technology and changing industry demands. Some of the key trends shaping the future of gearbox technology include:

Modern gearboxes are increasingly being equipped with IoT-enabled sensors that monitor parameters such as temperature, vibration, and load. This allows for real-time condition monitoring and predictive maintenance, reducing downtime and extending the lifespan of the gearbox.

With the growing emphasis on sustainability, manufacturers like RICHMAN are developing gearboxes that offer higher energy efficiency. This includes the use of lightweight materials and advanced lubrication systems to minimize energy loss.

3D printing technology is being explored for the production of complex gear components. This approach offers greater design flexibility and the potential for faster production times.

New surface treatment techniques, such as plasma nitriding and diamond-like carbon coatings, are being used to improve the wear resistance and durability of gears.

RICHMAN's commitment to quality, innovation, and customer satisfaction sets it apart in the competitive world of gearbox manufacturing. Here are some reasons why industries trust RICHMAN for their helical gearbox needs:

Proven Track Record: With years of experience in the industry, RICHMAN has built a reputation for delivering reliable and durable gearboxes.

Global Reach: RICHMAN serves clients across the globe, offering a wide range of products to meet diverse industrial needs.

Technical Expertise: The company's team of engineers and technicians are experts in gearbox design and manufacturing.

Customer-Centric Approach: RICHMAN works closely with its clients to understand their requirements and deliver tailored solutions.

Durability is a critical factor in the performance of industrial gearboxes, and RICHMAN UNIVERSAL SOURCING CO LIMITED has mastered the art of manufacturing helical gearboxes that stand the test of time. By combining superior materials, precision engineering, and advanced manufacturing processes, RICHMAN ensures that its products meet the highest standards of quality and reliability. As industries continue to evolve, RICHMAN remains committed to innovation, delivering gearbox solutions that drive efficiency and productivity.

For businesses seeking durable and high-performance helical gearboxes, RICHMAN is a name they can trust. With a focus on quality, customization, and customer satisfaction, RICHMAN is shaping the future of gearbox technology, one gear at a time.