Views: 0 Author: Site Editor Publish Time: 2025-04-30 Origin: Site

The evolution of mechanical components in modern engineering has been nothing short of revolutionary, with each advancement addressing the critical demands of precision, efficiency, and durability. Among these innovations, the RV Series Worm Reducer has emerged as a pivotal component in numerous industrial applications. This article delves into the evolution of the RV Series Worm Reducer, its significance in modern engineering, and how RICHMAN UNIVERSAL SOURCING CO LIMITED (hereafter referred to as RICHMAN) has been at the forefront of this transformative journey.

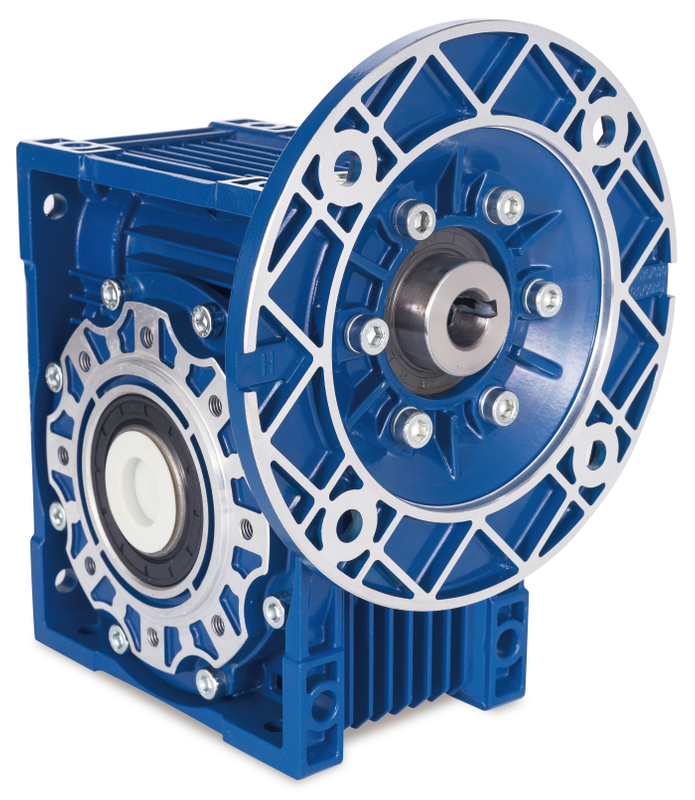

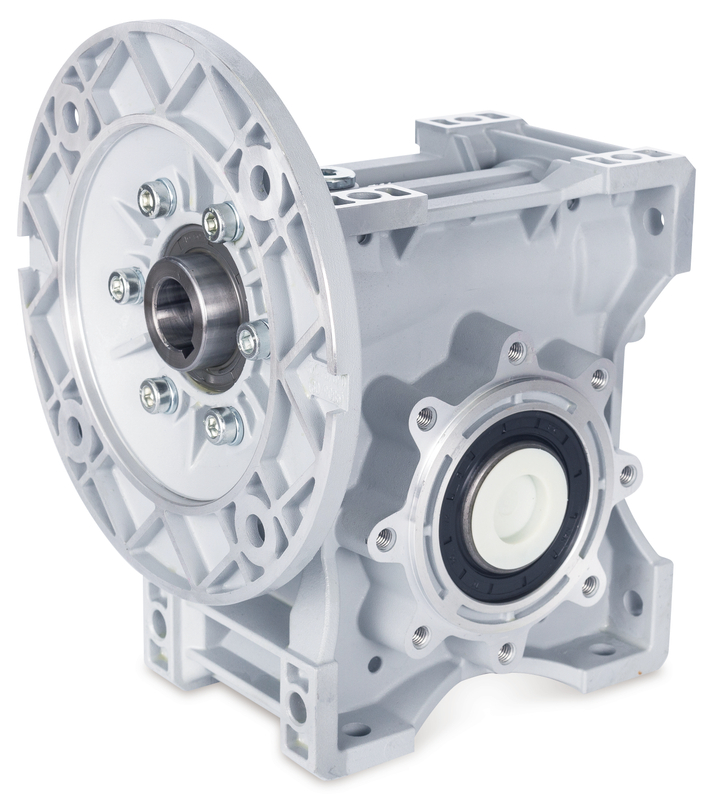

RV Series Worm Reducers are advanced mechanical devices designed to transmit power and reduce speed in a variety of applications. They are widely recognized for their compact structure, high torque transmission, and exceptional efficiency. Their unique design incorporates worm gears, which consist of a worm (a screw-like component) and a worm wheel, enabling smooth and quiet operation even under heavy loads.

These reducers play a crucial role in industries such as robotics, automotive, material handling, and manufacturing. They are particularly valued for their ability to deliver high reduction ratios in a single stage, making them ideal for applications requiring precise motion control and high torque output.

High Efficiency: Advanced gear design ensures minimal energy loss during operation.

Compact Design: Space-saving construction makes them suitable for applications with limited installation space.

Durability: High-quality materials and robust construction ensure long service life.

Low Noise: Smooth gear operation minimizes noise, enhancing the working environment.

Versatility: Suitable for a wide range of industrial and commercial applications.

The history of RV Series Worm Reducers is a testament to the relentless pursuit of innovation in mechanical engineering. Over the decades, these devices have undergone significant advancements, driven by the need for higher efficiency, greater reliability, and enhanced performance. RICHMAN has been a key player in this evolution, leveraging cutting-edge technology and expertise to develop state-of-the-art RV Series Worm Reducers.

The initial iterations of worm reducers were relatively simple, focusing primarily on basic speed reduction and torque transmission. These early models were often bulky, inefficient, and prone to wear and tear. However, they laid the groundwork for future innovations, highlighting the potential of worm gear technology in industrial applications.

With the advent of advanced materials and manufacturing techniques, worm reducers began to see significant improvements in performance and reliability. The introduction of high-strength alloys and precision machining enabled the production of more durable and efficient gear components. RICHMAN, recognizing the potential of these advancements, invested heavily in research and development, resulting in the creation of high-performance RV Series Worm Reducers.

The integration of modern engineering principles, such as computer-aided design (CAD) and finite element analysis (FEA), has further revolutionized the design and manufacturing of RV Series Worm Reducers. These tools allow for the optimization of gear geometry, ensuring maximum efficiency and minimal energy loss. RICHMAN has been at the forefront of this trend, utilizing state-of-the-art software and testing equipment to produce industry-leading worm reducers.

In recent years, the emphasis on energy efficiency has become a driving force in the evolution of RV Series Worm Reducers. As industries strive to reduce their carbon footprint and operational costs, the demand for energy-efficient mechanical components has surged. RICHMAN has responded to this challenge by developing worm reducers with optimized gear profiles and advanced lubrication systems, ensuring minimal energy loss and maximum performance.

As a leading manufacturer and supplier of RV Series Worm Reducers, RICHMAN has played a pivotal role in shaping the industry. The company's commitment to innovation, quality, and customer satisfaction has earned it a reputation as a trusted partner for businesses worldwide.

RICHMAN's state-of-the-art manufacturing facilities are equipped with the latest machinery and technology, enabling the production of high-precision worm reducers. The company's stringent quality control processes ensure that every product meets the highest standards of performance and reliability.

RICHMAN offers a comprehensive range of RV Series Worm Reducers, catering to diverse industrial needs. From standard models to custom-designed solutions, the company's product portfolio is designed to meet the unique requirements of its clients.

In line with its commitment to sustainability, RICHMAN has implemented eco-friendly practices in its manufacturing processes. The company uses energy-efficient machinery and recyclable materials, minimizing its environmental impact while delivering high-quality products.

The versatility of RV Series Worm Reducers makes them indispensable in a wide range of applications. Some of the key industries that benefit from these devices include:

Robotics: Precise motion control and high torque output make them ideal for robotic arms and automation systems.

Automotive: Used in automotive assembly lines and testing equipment for their reliability and efficiency.

Material Handling: Essential for conveyor systems, hoists, and cranes, ensuring smooth and efficient operation.

Manufacturing: Widely used in machinery for metalworking, plastics processing, and other manufacturing processes.

Renewable Energy: Playing a role in wind turbines and solar tracking systems, contributing to sustainable energy solutions.

The future of RV Series Worm Reducers looks promising, with ongoing advancements in materials science, manufacturing technology, and engineering principles. RICHMAN is committed to staying ahead of the curve, continuously innovating to meet the evolving needs of its clients and the industry at large.

One of the key trends shaping the future of worm reducers is the integration of smart technology. By incorporating sensors and IoT connectivity, these devices can provide real-time data on performance, enabling predictive maintenance and reducing downtime. RICHMAN is actively exploring these possibilities, aiming to develop next-generation worm reducers that combine traditional reliability with modern intelligence.

The evolution of RV Series Worm Reducers is a testament to the ingenuity and dedication of engineers and manufacturers like RICHMAN. These devices have come a long way from their humble beginnings, transforming into essential components that drive progress in various industries. As the demand for efficiency, precision, and sustainability continues to grow, the role of RV Series Worm Reducers in modern engineering will only become more significant.

RICHMAN UNIVERSAL SOURCING CO LIMITED remains committed to pushing the boundaries of innovation, delivering high-quality solutions that empower businesses to achieve their goals. With a focus on excellence and a passion for progress, RICHMAN is poised to lead the industry into a new era of engineering excellence.