Views: 0 Author: Site Editor Publish Time: 2025-04-10 Origin: Site

In the rapidly evolving world of industrial automation, the demand for efficient and reliable transmission solutions has never been higher. Among the various options available, helical gearboxes have emerged as a popular choice for many automation applications. This article delves into the reasons behind the growing popularity of helical gearbox solutions, with a special focus on the offerings of RICHMAN UNIVERSAL SOURCING CO LIMITED, commonly known as RICHMAN.

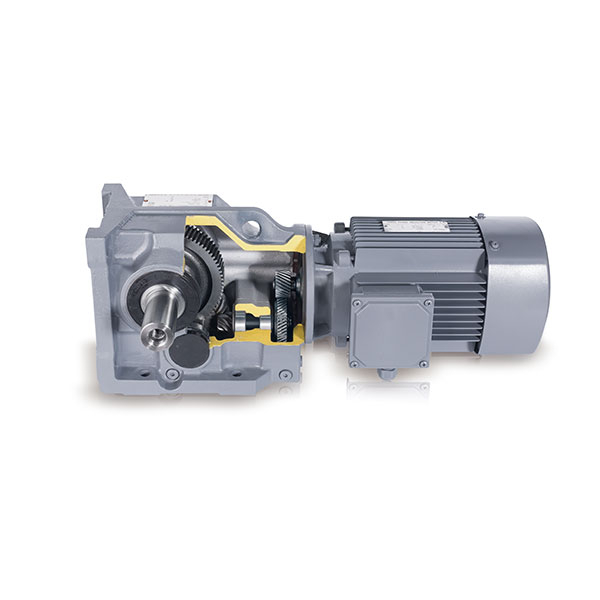

Helical gearboxes are a type of gear system where the teeth are cut at an angle to the face of the gear. This design allows for gradual engagement of the teeth, resulting in smoother and quieter operation compared to other types of gear systems like spur gears. The angled teeth also enable helical gearboxes to handle higher loads and operate at higher speeds.

The primary components of a helical gearbox include the helical gears, shafts, bearings, and the housing. These components work together to transmit power efficiently from one part of a machine to another, making them indispensable in various industrial applications.

There are several advantages that make helical gearboxes a preferred choice in automation:

Smooth and Quiet Operation: The angled teeth of helical gears ensure a gradual engagement, which reduces noise and vibration.

High Load Capacity: Helical gearboxes can handle larger loads due to the increased surface contact between the gears.

Durability and Longevity: The robust design of helical gearboxes ensures a longer lifespan, reducing maintenance costs.

Efficient Power Transmission: Helical gearboxes offer high efficiency in power transmission, which is crucial for energy-saving applications.

Versatility: These gearboxes can be used in a wide range of applications, from automotive to industrial machinery.

RICHMAN UNIVERSAL SOURCING CO LIMITED, or RICHMAN, has been at the forefront of providing high-quality helical gearbox solutions tailored to meet the specific needs of the automation industry. With a commitment to innovation and excellence, RICHMAN has established itself as a trusted partner for businesses seeking reliable transmission solutions.

RICHMAN offers an extensive range of helical gearboxes designed to cater to various industrial requirements. Their product lineup includes standard models as well as customized solutions that can be tailored to meet specific application needs. This flexibility ensures that clients receive gearboxes that perfectly align with their operational demands.

Customization options provided by RICHMAN include variations in gear ratios, materials, and mounting configurations. This level of customization allows businesses to optimize their systems for maximum efficiency and performance.

At RICHMAN, quality assurance is a top priority. Each helical gearbox is manufactured using state-of-the-art technology and undergoes rigorous testing to ensure it meets the highest standards of quality and reliability. RICHMAN's commitment to innovation is evident in their continuous efforts to improve product performance and incorporate the latest advancements in gear technology.

By investing in research and development, RICHMAN stays ahead of industry trends, ensuring that their products remain competitive and cutting-edge. This dedication to innovation has earned RICHMAN a reputation for delivering helical gearbox solutions that are both effective and efficient.

Helical gearboxes are used in a wide array of automation applications, thanks to their versatility and efficiency. Some of the key areas where these gearboxes are employed include:

Conveyor Systems: Helical gearboxes are widely used in conveyor systems to ensure smooth and efficient movement of goods.

Packaging Machinery: The precision and reliability of helical gearboxes make them ideal for packaging machinery, where consistent performance is crucial.

Robotics: In robotics, helical gearboxes provide the necessary torque and speed control for precise movements.

Material Handling Equipment: These gearboxes are essential in material handling equipment, offering the strength and durability needed for heavy-duty operations.

Automotive Industry: Helical gearboxes are used in various automotive applications, including transmission systems and powertrains.

To illustrate the effectiveness of RICHMAN's helical gearbox solutions, consider a case study involving a leading packaging company. The company faced challenges with their existing gear systems, which were prone to frequent breakdowns and required constant maintenance. This led to increased downtime and operational costs.

Upon consulting with RICHMAN, the company decided to upgrade their machinery with RICHMAN's customized helical gearboxes. The new gearboxes were designed to handle higher loads and operate at optimal efficiency, significantly reducing noise and vibration levels. As a result, the company experienced a notable improvement in productivity and a substantial decrease in maintenance expenses.

As the automation industry continues to evolve, so too does the technology behind helical gearboxes. Several trends are shaping the future of these essential components:

Smart Gearboxes: The integration of sensors and IoT technology is leading to the development of smart gearboxes that can monitor performance in real-time and predict maintenance needs.

Lightweight Materials: Advances in materials science are enabling the production of lighter yet stronger gearboxes, improving energy efficiency and performance.

Enhanced Efficiency: Ongoing research is focused on increasing the efficiency of helical gearboxes, reducing energy consumption and environmental impact.

Customization and Flexibility: The demand for highly customized and flexible gear solutions is driving innovation in design and manufacturing processes.

In conclusion, the popularity of helical gearbox solutions in automation is driven by their numerous advantages, including smooth operation, high load capacity, and versatility. RICHMAN UNIVERSAL SOURCING CO LIMITED has played a significant role in this trend by providing high-quality, customizable gearboxes that meet the diverse needs of the industry.

As technology continues to advance, helical gearboxes are expected to become even more efficient and sophisticated, further solidifying their place in the automation landscape. Businesses that invest in these advanced transmission solutions can look forward to improved performance, reduced maintenance costs, and a competitive edge in their respective markets.

RICHMAN remains committed to delivering innovative and reliable helical gearbox solutions, ensuring that their clients are well-equipped to meet the challenges of modern automation. By staying at the forefront of industry trends and technological advancements, RICHMAN is poised to continue leading the way in helical gearbox technology.